Wholesale Small Manual Feed Machine for Farm Use

Product Model: ZLSP flat die feed pellet mill

Production Capacity: 60-800kg/h

Scope of application: Used to process corn, rice bran, soybean cake, fish meal, cottonseed cake and other raw materials into high-density feed particles, suitable for livestock rearing, convenient storage and transportation.

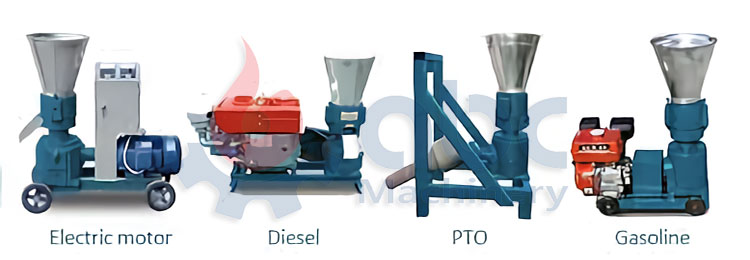

According to the power mode can be divided into: electric motor type, diesel engine type, gasoline engine type, PTO type

Buy Wholesale Manual Feed Pellet Machine at Factory Price

Manual Feed Pellet Machine & Small Feed Pellet Production Line for Farm Use

Small scale farmers and livestock breeders, that choose to adopt the farming method of formulating their own recipes, purchasing their own raw materials, and processing and configuring their own feed, buying wholesale small manual feed machines is their first choice, especially the hot sale small feed processing unit is the ideal choice.

Reliable Animal Pellet Machine Supplier & Manufacturer [ABC Machinery]

ABC Machinery is designed to provide cost-effective solutions for feed processing. Our machines are tailored to meet the needs of those looking for efficiency, simplicity and economy in their daily feed production operations. For more information, please feel free to contact us!

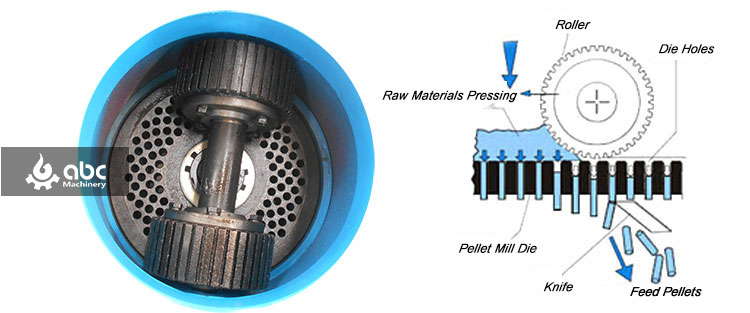

The Working Principle Of Manal Feed Pellet Making Machine

The pressure roller of the flat die pellet mill is fixed, and the flat die rotates with the shaft sleeve. Under the strong extrusion effect of the flat die and the pressure roller, the material is gradually compacted and squeezed into the die hole of the flat die, and in the die hole is constantly subjected to the pressure of the material squeezed into the die hole, and then penetrate out of the die hole, and then extruded into shape. The extruded material is cut into certain length of feed pellets by the cutter and thrown out from the discharging tray.

Replacement of flat die with different apertures can press different diameters of moulding materials.

Flat Die Feed Pellet Machine [Working Principle]

Various Animal Food That can Be Processed by small Feed Pellet Machine

The size of the pellet is controlled by the grinding disc and the cutter, the grinding disc controls the diameter of the pellet and the cutter controls the length of the pellet. The distance between the cutter and the grinding disc determines the length of the feed pellets, so what is the most suitable diameter of pellets for breeding chickens, ducks, fish, geese, rabbits? Depending on the type of animal to be farmed, the grinding hole of the grinding disc of the pellet mill to be chosen is also different.

As shown in the table below:

|

Aperture of grinding disc |

Applicable animals |

|---|---|

|

2.5mm |

small animal feeds such as young rabbits and chick |

|

3-4mm |

chickens, ducks, rabbits, geese, birds, aquatic fish and other feeds. |

|

5-6mm |

pigs, cows, sheep, horse and other feeds. |

|

7-12mm |

large animal feeds such as fish bait, large birds, rats, etc. |

Key Features and Benefits for Manual Feed Pellet Machinery

-

1. Compact Design for Small Operations:

Our small manual feed machines boast a compact design, making them suitable for limited spaces and small-scale operations. Whether you're running a backyard farm or a modest agricultural venture, these machines fit seamlessly into your workflow.

-

2. User-Friendly Manual Operation:

Designed with simplicity in mind, our feed machines feature manual operation, allowing users to have hands-on control of the feed processing. This user-friendly approach is particularly advantageous for those who prefer a straightforward and manageable production process.

-

3. Versatility in Feed Processing:

Despite their small size, our machines are versatile and capable of processing various feed ingredients. From grains and cereals to protein supplements, these machines ensure that you can create a nutritionally balanced feed for your livestock.

-

4. Reasonable Pricing for Affordability:

We understand the importance of cost-effectiveness for small-scale farmers. Our commitment to offering reasonable prices ensures that you can access high-quality feed machines without straining your budget. We believe in making essential agricultural tools accessible to everyone.

-

5. Durable Construction for Longevity:

Built with durability in mind, our small manual feed machines are constructed from high-quality materials, ensuring longevity and reliability. This robust design means you can depend on these machines for consistent performance over an extended period.

-

6. Easy Maintenance and Cleaning:

We recognize the value of time in daily farming operations. Our feed machines are designed for easy maintenance and cleaning, reducing downtime and allowing you to focus on the core aspects of your agricultural activities.

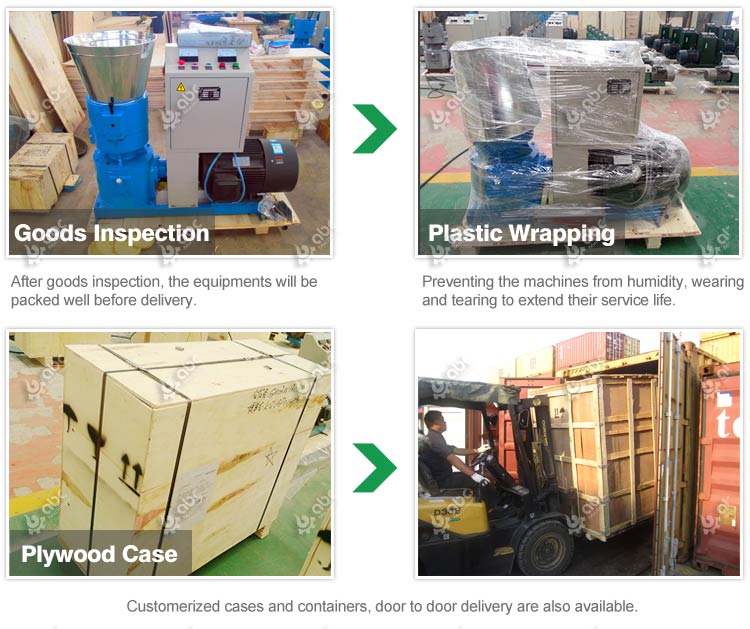

Packaging and Shipping Process

Investing in a Wholesale Small Manual Feed Machine at a reasonable price is a practical choice for small-scale farmers looking to enhance their feed processing capabilities. Our machines offer a combination of user-friendly features, versatility, and durability, making them an invaluable addition to your agricultural toolkit. Contact us today to explore how our affordable feed machines can contribute to the success of your farming endeavors.