1-3TPH Animal Feed Mill Project Proposal

Project Capacity: 1-3 ton/h

Application: It is used for processing feed pellet for pigs, cows, sheep, rabbits, chickens, ducks, fish, etc. Inaddition, it is suitable for the production of powder, concentrate and is a kind of multi-purpose animal feed pelletizing production line.

Common Raw Material: Corn and wheat, soybean, fish meal and fish oil, cottonseed meal, rice bran and bran, mineral and vitamin supplements, feed additives, grain by-products, and so on.

Animal Feed Mill Processing: Raw Material Reception, Cleaning and Grinding, Mixing, Feed Pelletizing, Cooling, Screening and Grading, Packaging

1-3TPH Animal Feed Mill Plant Project Proposal

The primary customer base for a 1-3 ton per hour animal feed pellet production plant includes poultry farms, livestock farms, aquaculture farms, individual breeders, feed distributors, and other feed manufacturing enterprises. These customers have diverse requirements, necessitating high-quality and diversified feed formulations to meet the nutritional needs of various animals, fostering their growth, production, and overall health.

[Factory Layout] 1-3tph Animal Feed Pellet Project Design

Therefore, when starting a 1-3 ton animal feed pellet milling business, paying attention to the following aspects can enhance the construction quality and operational efficiency of your own feed pellet production line.

-

Research Project Market

Conduct thorough market research before establishing the animal feed pellet plant to understand the local and target market demands, determining production scale, and types of feed. Additionally, implement effective marketing strategies before, during, and after construction to establish brand awareness and attract potential customers.

-

Select Project Site

Choose a suitable location considering factors such as transportation convenience, raw material supply, drainage systems, ensuring a smooth production process. Consider proximity to livestock farming communities for efficient distribution.

-

Define Project Layout

Design and construct a modern feed mill plant layout, incorporating areas for raw material storage, production, packaging, and administrative functions.

-

Consider Project Environmental and Sustainability Factors

Implement environmentally friendly measures during the construction process to minimize the environmental impact of production and comply with relevant environmental regulations. Additionally, consider the sustainability of the production process, including resource utilization efficiency, energy use, and waste management.

A successful establishment of an animal feed pellet plant requires thorough market research, careful site selection, clear project layout design, and consideration of environmental sustainability. To learn more about the construction process and obtain a detailed Animal Feed Pellet Project Report, do not hesitate to contact us!

Technical Details of the Small feed Pellet Plant for chicken & Cattle

Animal Feed Production Process:

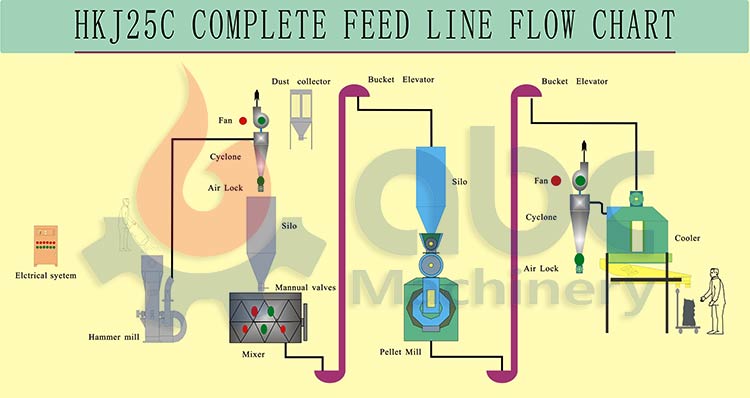

[Process Design]1-3tph Animal Feed Mill Processing flowchart

-

Raw Material Reception:

Efficiently managing and storing a diverse range of feed ingredients is crucial at the beginning of the production process. This involves the careful reception, handling, and storage of raw materials to ensure the availability and quality of ingredients for subsequent stages.

-

Crushing and Grinding:

This phase employs advanced hammer mill designed to precisely achieve the desired particle size.

-

Mixing:

Implementing mixers is vital for achieving thorough and uniform blending of ingredients. Modern mixing technology ensures that each batch is homogenous, guaranteeing a well-balanced composition of nutrients in the feed.

-

Pelletization:

The pelletization step utilizes high-capacity ring die feed pellet mills, employing pressure and heat to shape the blended ingredients into uniform and high-quality feed pellets.

-

Cooling:

After pelletization, the feed pellets undergo a cooling process using coolers. This step is critical to maintaining the integrity of the pellets, preventing deformation or degradation caused by the heat generated during the pelletization process.

-

Packaging:

The final stage involves the use of automated packaging machines for efficient and precise packaging of the feed pellets. Automation ensures consistency and accuracy in packaging, facilitating streamlined distribution and storage.

Hammer Mill

Ring Die Feed Pellet Mill

Cooler

Automatic Packaging Machine

3 Notes for Equipment Selection:

1. Carefully choose crushers, mixers, pellet mills, coolers, and packaging machinery based on efficiency, durability, and ease of maintenance.

2. Prioritize equipment with energy-efficient and environmentally friendly features.

3. Integrate an advanced control system to monitor and optimize the production process.

Financial Considerations for Your Animal Feed Mill Project

Animal Feed Processing Project Investment Estimate:

-

Provide a detailed breakdown of capital expenditures, including land acquisition, construction, equipment purchase, and installation.

-

Projected operational costs such as raw material procurement, labor, utilities, and maintenance.

-

Present a comprehensive financial model projecting revenue, operating expenses, and potential profits over a specified period.

Setting up a 1-3 TPH animal feed mill plant represents a strategic investment in meeting the increasing demand for high-quality animal feed. If you are intrested in start a poultry or livestock animal food making factory, please feel free to contact us! We are here to provide further information and support for your feed pellet production venture.