100 ton/h Poultry Feed Manufacturing Plant

Project Name: Livestock & Poultry Feed Manufacturing Plant

Feed Plant Capacity: 100 tons feed pellets can be made per hour, which is equal to 600,000 tons per year.

Application: It is suitable for processing various feedstuff into feed pellets for different livestock and poultry animals.

(Small Scale Project: 5 ton/h Cattle Feed Pellet Plant )

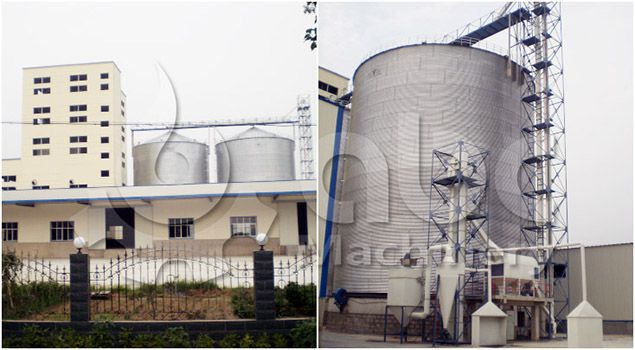

Feed Manufacturing Plant Photo Display

Finished Poultry Feed Making Factory

Photos were took during the factory construction and some of them are listed below. Please feel free to get in touch with us and tell us your needs and cost budget, then we will help you make the best customized project plan.

Feed Mill Dispaly

Batching Equipment Details

Equipment Details

Roughage Feed Manufacturing Production

Roughage feed is as feed with a low nutritional value which has a high level of crude fiber in the dry matter its normally above 18%. The low nutritional value is caused by its large size, the level of fiber and the difficulty it has when digesting the feed. it has a high fiber content making roughage the major source of feeding herbivorous livestock’s. (Product List of Our Feed Manufacturing Machines >> )

Feed Products for Domestic Animals

Processing and utilization of roughage

- Wetting and soaking: This process softens the forage and helps to eliminate tannins and abnormal smell. Sediments which are available can also be removed. It also produces organic acids like lactic acid. This increases the process of digestion and feeds intake. In addition, it adds nutrients to the roughage.

- Cutting and crushing: This process is important as it enables the animal to stir, eat and chew. The feed is cut into different sizes depending on the type of animal and its age.is the size is too long then it's useless. On the other hand, small sizes affect the process of chewing and chewing the cud. Crushing can process it into various forms of grass powder. Some types of feed are not suitable for crushing like the coarse fodder for ruminants. This is because it's dangerous for rumination and it affects how the feed is digested.

- Ammonization: Is used to increase the level of protein of the feed and also it increases the feed intake of the livestock.

- Fermentation: It increases the nutrient content of the feeds as it breaks down fiber which is hard for the animals to digest.

- Pelleting: During this process, the grain aleuronic layer's cell wall is destroyed through the function of mechanical force and steam treatment. This makes important ingredients to be released by the aleuronic layer which is absorbed and utilized by livestock and poultry. In addition, after feed pellets have been produced, the level of crude fiber is reduced, carbohydrate is partially broken down and the starch is gelatinized, thus energy utilization of feed is improved. Pelletization can also improve how certain nitrogen base acids are utilized. And how phosphorous is used efficiently for the benefit of livestock. (Related Equipment: Large Poultry Feed Mill Machine )

benefits of Livestock & Poultry Feed pellets

Poultry Feed Pellets

Feed pellets are far much superior to powder feed or mash feed in the following ways:

- Feed pellets are highly stable and does not get easily destroyed.

- They are suitable for storing, easier to handle and transport.

- Pelletizing process minimizes feed wastage which can result from selective feeding.

- Pelletizing increases feed density.

- Increase the amount of feed taken.