Wood Pellet Production Guide

In today's uncertain times, saving money is essential and using a pellet stove will certainly help you save in the long run. More people are seeing the advantages of pellet stoves and are converting over. With this, the demand for wood pellet fuel has surpassed the demand. So now there is a new market that is "How to make Wood pellets at Home". ABC Machinery has created small pellet presses that we can use at home to manufacturing small scale wood pellets.

You will be surprised, but not only wood can be made in these machines but raw materials like wood waste, straw, grasses and energy crops like corn to name a few, which are known as biomass palls fuel. Making biomass fuel is a skillful process and requires some degree of knowledge and understanding of the equipment used. This is where the eBook helps as it gives you the sound understanding of the processes involved to make your pellet fuel. The guide will explain in 10 simple steps the processes that begin as the raw product and then to the end as the finished pellet fuel.

Here's a Brief Breakdown of What's Inside the Pellet Production Guide:

The Future Potential of Biomass Pellet Fuel

It will explain the production process involved and how the heat and pressure are used to re-form the pellets. Also explained is the way that natural lignin and moisture content will affect the quality and production.

- Production Process and Principles

In the Wood Pellet Making Machine Guide, it will be explained the steps involved in the process of production and detail teach you what's happens with heat and pressure to form the pellets

- Equipment and Machinery

Different types of equipment and machinery are to be used that will depend on the size and scale of the production involved and, of course, the type of biomass fuel you are going to make.

Each of the mills mentioned will come with there own advantages and disadvantages that are clearly explained in detail. Factors that will affect your choice are the speed of the, machine, metals involved and of course what type of pellet fuel you are,making.

- Binders and Mill Lubricants

Depending on the raw material that you are using, you may require lubricants and binders and these will improve the quality and productivity of your mill.

This process will be easiest using a chipper or hammer mill the size of your material down until it is large enough to fit. You can use a chipper or hammer mill to reduce in without damaging the blade of the machine. Some wood will need to be dried, as the moisture content of wood used for wood pellets should be anywhere from 10-20 percent. The machine will basically take care of the rest as long as you have your supplies proper and these are the basic steps involved to make your own wood pellets.

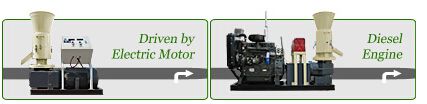

How to Choose A Pellet Press

Making wood or biomass pellets requires a pellet making machine, also known as a pellet mill or pellet press. If you're one of a developing number of individuals, you may either be researching how to make wood pellets, or you're searching for information about the various sorts of pellet factories required to create pellets. When you first start researching the pellet making process, you'll see that there are just two different sorts of pellets plants that are utilized to make pellets. The difference between these two decisions comes down to the sort of die that they use to form the pellets. These two sorts are known as the ring die sort pellet press and the flat die sort pellet press.

In either case, you have to understand completely the basics of pellet presses before you make any purchasing decisions. The accompanying information is aimed at offering you some assistance with making an informed decision before you purchase a pellet plant. Remember that the most important bit of hardware you'll have to make pellets is the pellet mill press, so make sure to thoroughly familiarize yourself with their operation.

Ring Die Pellet Mill

The main is the ring die sort pellet mill. As the name suggests, it utilizes a ring die to form the pellets. The ring die itself is a thick metal cylinder with holes drilled through the cylinder around the circumference. Inside the ring are the rollers that are utilized to push the material through the die. Raw materials as wood waste or biomass are nourished into the focal point of the ring, and the rollers force them through the holes of the ring die. The formed pellets then rise up out of the outside of the die. This sort of pellet machine is what you'd find in a commercial pellet plant that creates a high volume of pellets. The ring dies sort plant is a high cost, heavy obligation machine that's largely out of the value range of the vast majority that make their wood or biomass pellets.

Flat Die Pellet Mill

Next is the flat plate die sort pellet mill. This machine uses a flat plate to form the pellets. If you can imagine a meat processor, the die utilized as a part of it is fundamentally the same to that of the flat plate style pellet factory. The die is made from a thick round flat plate with many holes drilled through it. An arrangement of rollers ride on top of the plate, and when the raw feedstock is encouraged into the machine, the die turns along with the rollers.

To show signs of improvement idea of how this arrangement works, imagine a wheel on the edge of a record player. This consolidated die and roller action force the raw material through the die causing formed pellets to exit on the underside of the die, where they fall into a chute and leave the machine. The flat plate sort pellet plant is typically a great deal less costly than its ring dies counterpart, and are for the most part utilized by do-it-without anyone's help pellet makers.

They're also relatively easy to work on, and can be fueled by some different strategies. This, thusly, loans to the appeal of the flat die pellet mill plant (mobile pellet plant) to the small scale maker. By using an influence source that you may already own,you can save a ton of cash by purchasing yourself a small home use pellet press.