how to turn barley fodder into pellets

There are a number of ways in which fodder can be turned into pellets, which can then be used in various industries. This is done through grinding the fodder and then passing these ground materials through a grass pellet press.

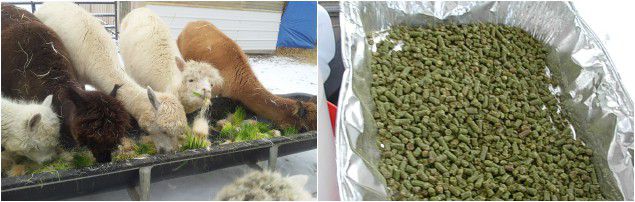

How to make animal feed pellets from barley fodder?

A feed pellet press, or feed mill as it is likewise known, is a sort of machine that is used to make feed pellets from grass, grain, straw... Animal feed ellet presses combine trivial material into larger and more substantial materials.

Barley Fodder Pellet Press for Sale

There are two types of feed pellet machine used in animal feed pellet production. These are the ring die pellet press and the flat die pellet press. These are outlined below:

- Flat die feed pellet presses utilize a flat die with a number of apertures. The powdered material to beturned into pellets is brought to the top of the flat die and while the die take tums, a roller compresses the crushed raw material into the holes of the flat die. There is usually a harvester on the opposite side of the flatdie which cuts the now bare pellet out from the flat die.

Electric Pellet Mill |

Model | ZLSP150B |

|---|---|---|

| Driving Mode | Electricity | |

| Power | 4KW | |

| Capacity | 50-90 kg/h | |

| 110-200 lbs/h | ||

| Weight(NW/GW) | 95-110 kg | |

| 210-250 lbs | ||

| Packing Size | 800*450*700mm | |

| 31*18*28inch |

Diesel Driven Pellet Mill |

Model | ZLSP150A |

|---|---|---|

| Driving Mode | Diesel Oil | |

| Power | 8HP | |

| Capacity | 50-100kg/h | |

| 110-220lbs/h | ||

| Weight(NW/GW) | 180-220kg | |

| 400-490lbs | ||

| Packing Size | 1000x500x750mm | |

| 39*20*30inch |

Gasoline Pellet Machine |

Model | ZLSP150Q |

|---|---|---|

| Driving Mode | Gasoline | |

| Power | 13HP | |

| Capacity | 50-100kg/h | |

| 110-220lbs/h | ||

| Weight(NW/GW) | 180-220kg | |

| 400-490lbs | ||

| Packing Size | 1000*500*750mm | |

| 39*20*30inch |

PTO Pellet Press |

Model | ZLSP150P |

|---|---|---|

| Driving Mode | PTO (Power Taken Off) | |

| Power | ≥10HP | |

| Capacity | 50-100kg/h | |

| 110-220lbs/h | ||

| Weight(NW/GW) | 90-110kg | |

| 200-245lbs | ||

| Packing Size | 900x540x1020mm | |

| 35*21*40inch |

- Ring die feed pellet press is comprised of a bunch of radial slot all over the die. The powderedmaterial is put into the ring die and then evenly spread across it evenly by spreaders. A couple of rollers arethen used to compress the powdered material through the holes of the ring die. A couple of cutters are thenused to cut the pellets out from the other of the ring die.

| Model | Capacity | Main Motor Power | Feeding Motor Power | Conditioner Motor Power | Diameter of Ring Die | Diameter of Final Feed Pellets |

|---|---|---|---|---|---|---|

| SZLH25 | 1.0-2.0T/H | 11kw*2 | 0.75kw | 2.2kw | 250 | 2-10mm |

| SZLH35 | 3.0-5.0T/H | 30kw*2 | 0.75kw | 2.2kw | 350 | 2-10mm |

| SZLH42 | 6.0-10.0T/H | 55kw*2 | 0.75kw | 5.5kw | 420 | 2-10mm |

| SZLH520 | 8.0-15T/H | 75kw*2 | 0.75kw | 5.5kw | 520 | 2-10mm |