Complete Wood Pellet Line

Why Choose ABC Machinery?

Flowchart of Pelletizing Process

- No.1 market share in China, more than 170 wood pellet lines built in around the world. Convenient for your on-site investigation.

- 10 patents innovation technology guarantees the quality of every equipment of pelletizing projects for customers, eg. the smart cooling system, the 3 cylinder dryer, etc.

- The capacity can reach up to 150,000T/Year.

- PLC intelligent control. Smart and reliable!

Drawings of Complete Wood Pellet Production Line

This is an project plan for Medium Scale Complete Wood Pellet Line with 2 sets of pellet machine.

The followings are a factory layout example for industrial large scale production line (designed with 4 sets of pellet machine). It includes processes of crushing, drying, pelletizing, cooling and packaging.

Crushing system with Dust collector, it is a serious consideration on how to protect the health for operators. Dust collecting system is very important, we used the Bag dust collector in Hammer mill section, and the water film Dust collector in the whole of plant.

Drying system is the key part of the whole pellet plant. This is a drum drier has fireproofing and moisture checking designing. The fuel can be various, but you can only choose one as the fuel.

This plan was designed according to Humanization Design. It has a cycle water pool for collect the dust in operation.

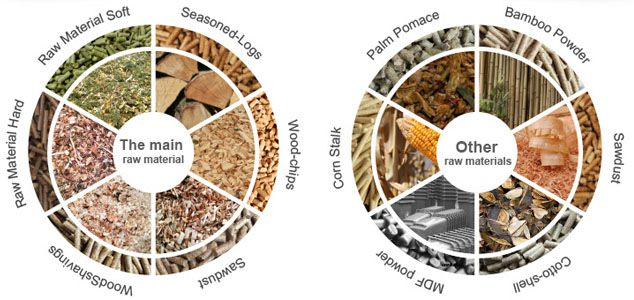

What Kind of Materials Can Be Processed By Our Pelletizing Line?

This complete biomass pellet production line can process many kinds of raw materials suca as groundnut shell, sugarane biogases, caster shells/stalk, sawdust, coffee husk, paddy straw, sunflower stalk, cotton stalks, tobacco waste, mustard stalk, jute waste, bamboo dust, tea waste, wheat straw, palm husk, soybeans husk, coir pitch, etc.

Details of Pellet Line Equipment

Debarker

Wood Chipper

The wood chipper is advanced equipment to produce wood chips and ia used in paper plants, pellet plants, particle board plants and fiber-board plants. It cuts logs and small pieces of wood into hight quality chips of even length and uniform chip thickness. It is also suitable for the chipping of branches, twigs and planks.

Screener / Sieving Machine

This screener is cylinder type. It is specially designed to sieve out big-sized materials in order to keep them from going into a pellet mill. Thus the pellet mill can be well protected from being chocked.

Hammer Mill / Crushing Machine

- It is specific pulverizer for wood chips, shavings, rough sawdust, etc. The pulverizing room is designed to be wide for wood's crushing.- Well balanced rotor makes the running very stable.

- The special connection of coupling makes it less vibration and easier to be installed.

Single-layer Revolving Cylinder Dryer

- The rotary dryer is the choice for high throughput capacity applications involving high moisture, friable, fee-flowing materials and by-products.- A rotating drum and strategically positioned flights combine to lift and shoer product evenly through the air stream.

- A thermostatically conrolled discharge air temperature assures precise final moistures and allows sensitivity to varying product conditions.

- Single-pass or three-pass configurations are available to match product characteristics.

- Heating options include steam, gas, oil, and themal oil.

Pellet Mill (making pellets)

- Applying a quick-release hoop type ring die and a high-precision main drive gear increases the efficiency of pelletizing wood by 20% over a belt drive type pellet mill machine.- Timing feeder can control the feeding speed to reduce the block ratio.

- The body is more durable because we use spherical graphite cast iron.

- Capacity increased after adding another force feeder made from stainless steel to increase the feeding spread area.

Cooling System of Pellet Mill

- Adpoting aerodynamics technology and the current round principle, reduces the temperature in pelletizing chamber to around 90℃。 As a result the machine can work well continuously.- Controls temperature & exhuasts extra steam through air circulation. As a result, performs well in non pressing areas to extend the life of ring die and brarings.

- The machine can run continuously.

Pellets Cooler

- Auto control cooling period. It makes the fresh pellets hard & dry. Cool air flows from bottom to top, while the pellets drop from top to bottom, they fully meet and cool completely.- The manufacturing steel plates are 3mm thick.

-The cooling system consits of vessel, wind-in cone, discharge system, feed port, exhaust inlet, level control indicator.

- This equipment should be used with air lock feeder, cooling wind net.

Pellets Packing Machine

- Including automatic scale, conveyor, heat sealing devices for wood pellets.- This machine is a combination of automatic weighting and filling, together with transportation sewing machine, so that it can automatically weigh, fill and sew.

- Computer high-speed smapling and processing, as well as the programmable control process ensure that it is universal to different packing.

- The special aseismic equipmetn can guarantee precise calculation, fast speed and stable work under bad conditions. It can be adjusted outside which is very convenient to maintain.

- It is widely used in bagging of wood pellets, animal feed pellets and powder materials.

Projects of Biofuel Pellet Plant

Here are some photos about one of our projects for your reference. It is designed and built for one of our client in Chile. The production output is 4.5~6 ton per hour. Don't hesitate to contact us for detailed business plan and project cost! We are always here to serve you!

4.5~6 ton/h Wood Pellet Plant Project in Chile

Details of the Crushing Section

Details of the Pelletizing Section

Our pellet plants have been built in the following countries:

| Europe | Germany, France, Lithuania, Republic of Ireland, Italy, Portugal, Czech, Hungary, Romania, Slovak Republic, Serbia, Montenegro, Bulgaria, Russia, Ukraine, Poland, Belarus, Croatia, Latvia, Sweden |

|---|---|

| Asia | China, Malaysia, Indonesia, Thailand, Viet Nam, India, Sri Lank |

| North America | the US, Canada |

| South America | Uruguay |

| Oceania | Australia |

- Send me a quote on a turnkey sawdust Ring Die Pellets making plant. I have a sawmill plant in Nigeria, I wanted to use the sawdust for making Pellets aand BBQ Charcoal. Diameter:4-8mm. Thanks.

-

Please note ABC Machinery is an engineering company specialized in designing, manufacturing, engineering, installation and commissioning of the turn-key project in this fields.

Enclosed pls find the catalogue for your reference. We hope we can co-operate with your esteemed company, and hope this is a good start for such a promising mutual beneficial course.

Regarding to your inquiry,in order to give you the right design,please give us the information below:

1.what's the capacity you need for the pellet and the BBQ charcoal?

2.what's the moisture content of the sawdust you have?

3.Is there any other material besides the sawdust?

4.when do you plan to start prodction?

Look forward to hearing back from you. - Thanks for your reply. I have a sawmill operation in Africa. I generated a lot of sawdust, I would like to turn them to pellets and charcoal. The pellets dimeter will be 4-8mm, the charcoal size will be 40mm x 40mm x 28mm. the sawdust moisture is 40-50%. There is no other raw material. The plant will commence from April 2012. I need a production plant machinery.

-

Please find the flowcahrt attached for you in email, here is the description:

There are two parts of the prduction,the pellet line and the briquette line.The main line is the pellet line,the two lines will share the pretreatment section such as pre-cleaning sieve and the drum dryer,the pellet mill and the briquette machine will get the ready sawdust from the drum dryer;then the cooler and sieve will after the pellet mill while the briquette will go to the kilns(we will give you the drawing for the kiln so you can set up at local by yourself) for burning to charcoal.

The flowchart is like what we discussed through the phone,please have a look first to see if there is anything need to change. - Hello, Im very intresting in biomass pallets production line. Please send me a quote for a 6t full production line. How much does it cost ? -- from Portugal

-

Before sending the offer, can you inform some information of your raw material? such as size and moisture. Then we can ensure whether crusher and dryer is needed in the offer.

Another question is for the pellet bagging machine, there are two kinds: one is small bag bagging machine such as 15kg-25kg per bag, another is jumbo bag bagging machine such as 800-1000kg per bag. Which one do you prefer to? - Can these pellet plants and machines process EN plus grade fuel pellets?

- A variety of factors come to play in ensuring the pellet machine produces high-quality fuel pellets. Such factors include, ash content lower than 0.5 percent and fine dust content lower than 1 percent for wood fuel pellets. Our pellet plant and machines are sufficient enough to produce EN plus grade pellets. Note, however, that to achieve desired results you must use the right raw materials. If you are using tree bark as your raw material, for example, you must ensure that the wood content stands at zero in order to have 0.5 percent ash content.

- Can you make pellets out of grass and straws or other biomass materials?

- Yes. Our wood pellet machines are able to process numerous types of biomass materials including hemp shiv, switchgrass, and Miscanthus among others to make fuel pellets. Note however that such materials produce increased amounts of ash compared to wood pellets.